Boscastle Locomotive Limited

16th August 2013

10th May 2013

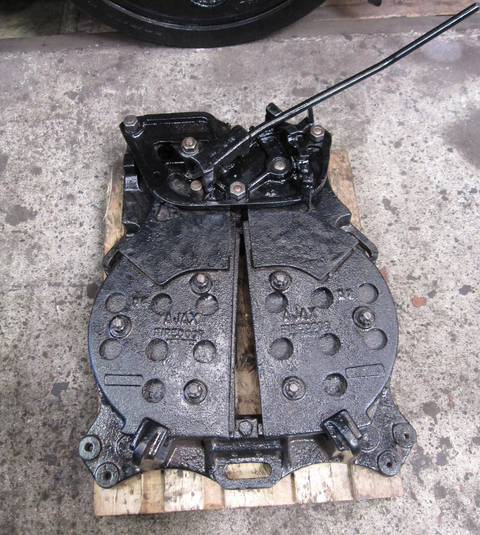

The overhauled firehole doors. These were in a terrible state when we retrieved them from the container, but we were pleasantly surprised to find that after a good clean they required no remedial work, other than a coat of heat-proof paint.

6th June 2013

The right hand rear plate on the cab, which typifies the kind of work required. A section of the old plate that was buckled by rust has been removed to allow the corroded angle iron to be renewed. A new piece of plate will be welded back once the angle has been replaced.

5th July 2013

This is the overhauled reverser gear mechanism. Worn seals had allowed abrasive grit to enter this part, so one gear shaft has been skimmed in a lathe, new bronze bushes made and new seals fitted. A final clean and a coat of paint has returned this item to as-new condition.

18th July 2013

The manifold having all its worn faces skimmed on a milling machine. The manifold sits in the cab, on top of the firebox, and steam from the boiler is passed through this at a pressure of 250PSI to the auxiliary equipment, which includes the injectors and blower. The smoother the manifold faces are, the less likely it is for pipes and valves bolted to it to leak where they are attached.

31st July 2013

Shown here is some of the most recent work on the locomotive. The old middle cylinder front-valve liner has been removed, with the second rear liner to be tackled when weather prevents us from working outside. The old liner, which has been cut in order to extract it, is sat next to the material purchased to replace it, and the rear liner. Machining will be carried out by one of our volunteer machinists, Ken King (if we can persuade him).

26th July 2013

Finally, it’s been a long time coming, but our tender has at last arrived at Loughborough. As soon as the weather cools we will make an inspection of the tank to assess its condition, though no serious work can be undertaken until the tender is at the shed. Our thanks go to Craig Stinchcombe and the full time staff for finding space for the tender at Loughborough, and for organising the move from Quorn.

Images on this page are copyright A.J.Morgan