Boscastle Locomotive Limited

February 2021

Tender

Work to the tender frame is still the main focus of attention, the last of the tender hornguides have been ground flat but not before we had to straighten the alignment of the right hand leading guide by heating and jacking the adjacent frame plate.

Thankfully, completion of this task has allowed us to dismantle the horngrinding machine at long last and save our shins from further collisions with it!

A start has been made on stripping the old whitemetal from the tender axleboxes and a chill (former) for casting the new metal onto them has been fabricated.

Most of the parts are in hand to complete the tender tank the main outstanding items being the two vacuum reservoir tanks for the tank top.

Boiler

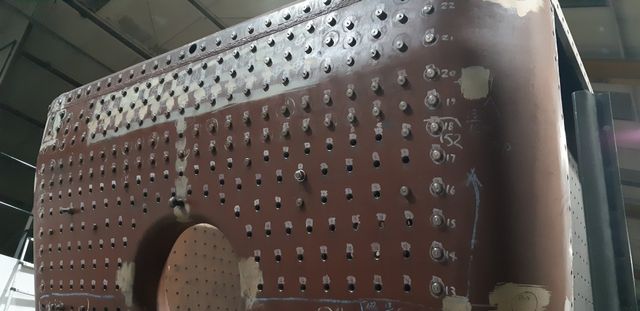

Boiler work also continues with the bottom half of the firebox rear stay holes tapped to final size and the first batches of steel and monel stays fitted. We are currently awaiting the delivery of longer stay taps to complete the firebox rear.

In the meantime we have removed all of the old studs from the firebox rear and refurbished the corroded gauge glass and regulator stuffing box mounting faces. Two washout plug holes have also been drilled and tapped in the new rear plate work and sixteen old washout plug holes re-tapped on the top rows of the sides and rear.

Images on this page are copyright A.J.Morgan